Link to YouTube video

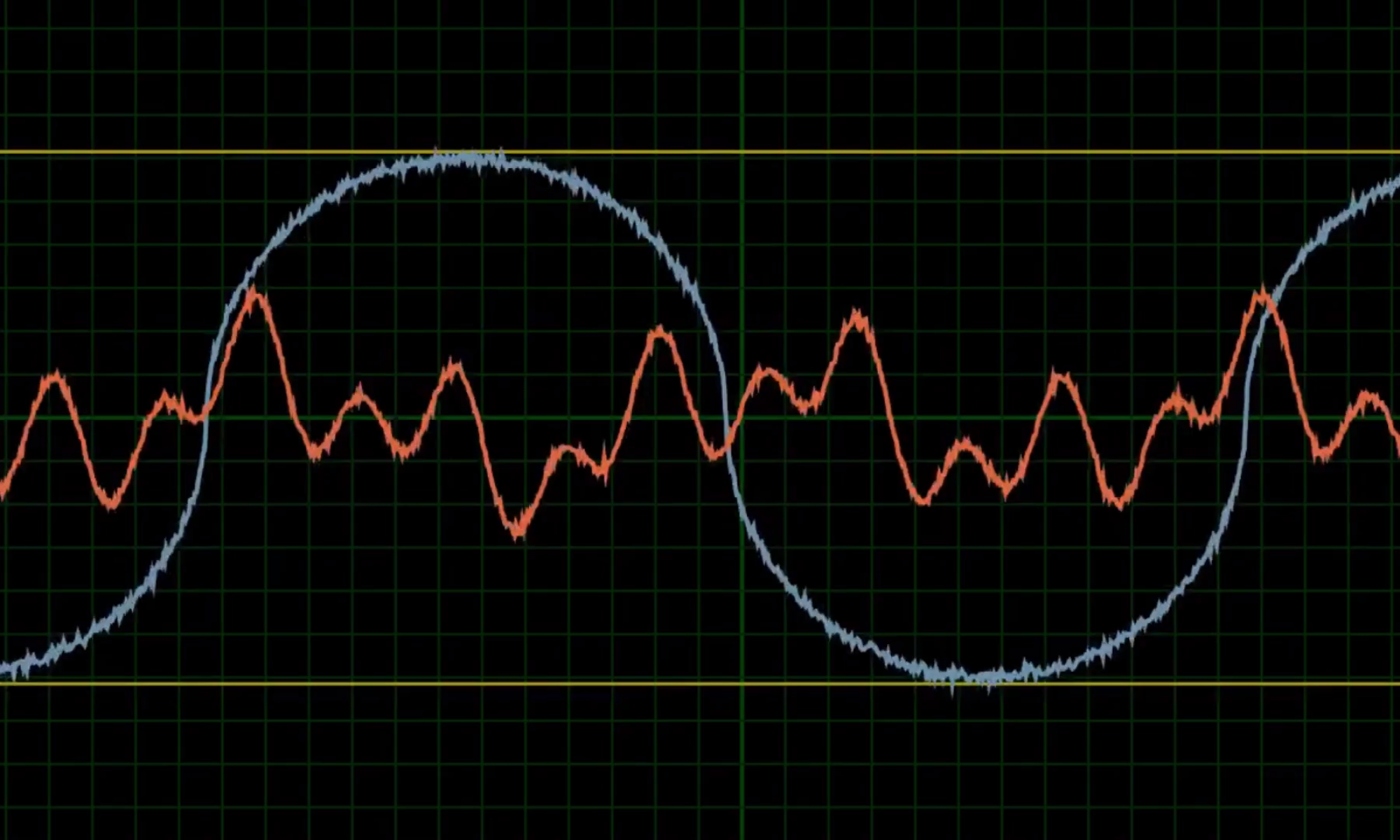

Rolling element bearings are in most of the rotating equipment that makes up the modern world. The downtime of rotating equipment due to bearing failure can be prevented by using sensor information to predict faults. However, a replicable bearing failure method is necessary for operators to interpret sensor data and reliably detect faults in industrial equipment. Bearing failure testing is conducted on small scale test rigs and often have a poor explanation of the experimental design. This study develops a method for inducing bearing failure on an industrial piece of equipment using lubrication and contamination of the bearing to induce failure in a short amount of time. The findings from this research show that failure can be induced through mixed grease contamination within one hour of testing. There are some great photos of vibration analysis resulting from this.

Author: Aseem Maroo, Masters of Professional Engineering (Mechanical) 2020