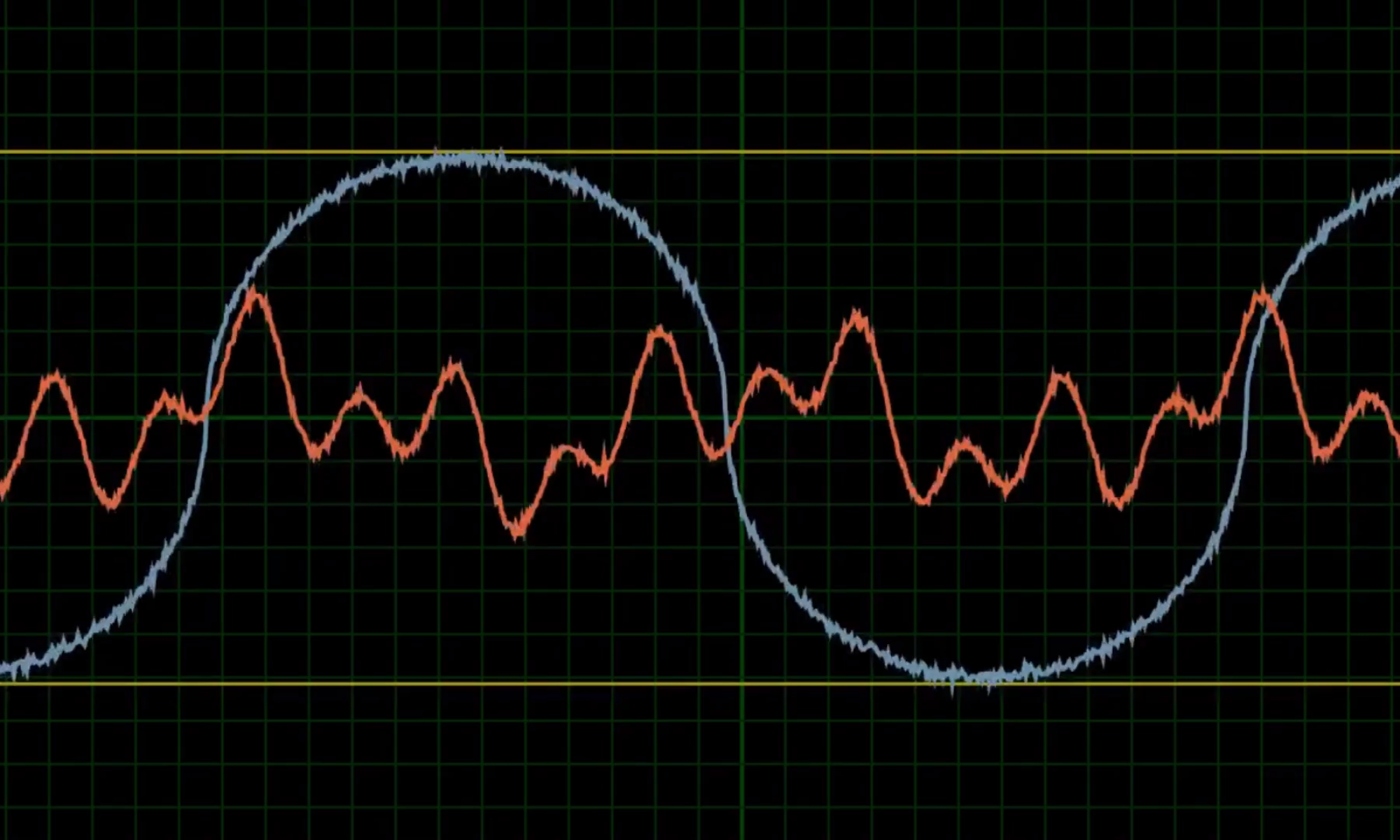

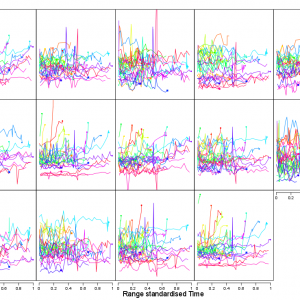

Vibration measures can be used to predict bearing failure in machines with rotating parts. Surface defects on bearings cause periodic vibration during rotation. The predictor is longitudinal, endogenous and intermittently measured with error. Methods have been developed which model both the risk and the longitudinal covariate probabilistically, though few examples exist in asset maintenance. For instance, Sundin et al. (2007) models the longitudinal as a discrete state Markov chain process. Joint models (for longitudinal and survival data) provide efficient parameter estimates of association between endogenous longitudinal covariates and event times. This is the first example of such an approach, as developed in the medical literature, applied to an observational dataset in the field of asset maintenance. The dataset we consider, reported in a series of journal articles (Banjevic and Jardine, 2006; Lin et al., 2006; Heng et al., 2009; Tian et al., 2010) and a conference procedure (Sundin et al., 2007), comes from the Irving Pulp and Paper Mill in New Brunswick Canada.

The model we develop consists of a longitudinal cubic B-Splines mixed effects submodel and a Weibull proportional hazards submodel. We assess each feature for association with bearing failure and prospective accuracy. Prospective accuracy is assessed with a Receiver Operating Characteristic (ROC) curve. In contrast to other papers which report on this dataset, we find that the time-domain acceleration feature P1V Gs should be used for decision making rather than the high frequency band spectral feature P1V Par5. Although P1V Par5 is a good measure of fault progression, it has lower prognostic accuracy compared to P1V Gs. We also provide directions for further work, with an adapted forward selection process and a change-point model.